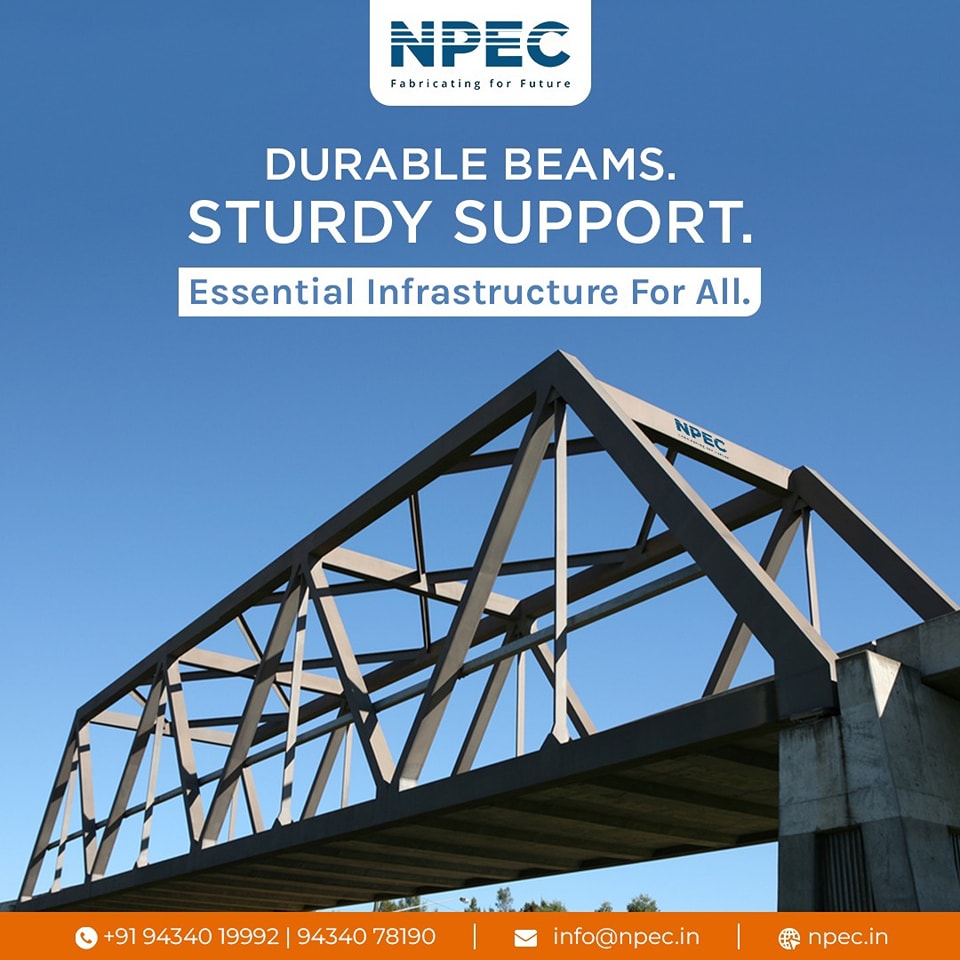

Steel girder bridges are a common type of bridge structure that use steel girders as the main load-bearing element. These bridges are prevalent in modern infrastructure due to their strength, durability, and versatility. Here are some key points about steel girder bridges:

- Structure: Steel girder bridges typically consist of steel beams (girders) spanning between supports such as piers or abutments. These girders support the bridge deck, which carries the traffic loads.

- Types of Steel Girders:

- Plate Girders: Built-up girders fabricated from steel plates and connected by welding or bolting.

- I-Beams: Standard shapes that resemble the letter “I” in cross-section, efficient for spanning long distances.

- Box Girders: Hollow rectangular or trapezoidal shapes that provide additional strength and stiffness.

- Advantages:

- Strength: Steel has a high strength-to-weight ratio, allowing for lighter bridge decks and reduced foundation costs.

- Durability: Steel is resistant to corrosion with proper maintenance, making it suitable for long-lasting structures.

- Speed of Construction: Steel components are often prefabricated off-site, allowing for faster assembly and less disruption to traffic.

- Applications:

- Highways and Roads: Steel girder bridges are commonly used for highway overpasses and interchanges.

- Railways: They are also used for railway bridges due to their ability to span wide distances and carry heavy loads.

- Pedestrian Bridges: Smaller steel girder bridges are used for pedestrian and bicycle crossings.

- Maintenance: Regular inspection and maintenance are crucial to ensure the structural integrity of steel girder bridges. This includes inspections for corrosion, fatigue, and other potential issues.

- Design Considerations:

- Span Length: Steel girders can span a wide range of distances, from short spans to long spans exceeding 100 meters.

- Load Capacity: Designs must consider the anticipated traffic loads, including vehicles, pedestrians, and possible future expansions.

- Special Designs:

- Movable Bridges: Some steel girder bridges are designed to open or move to accommodate marine traffic, such as bascule or swing bridges.

- Cable-Stayed Bridges: These bridges combine steel girders with cables for additional support over longer spans.

Overall, steel girder bridges are a vital component of transportation infrastructure worldwide, offering strength, durability, and economic efficiency in construction and maintenance.

A steel girder bridge is a type of bridge in which the primary support structure consists of steel girders. These girders are horizontal beams that bear the load of the bridge deck and distribute it to the piers or supports. The steel girders can be of different shapes and configurations, but the most common types are I-beams and box girders. Here are some key characteristics:

- Material: Made primarily of steel, which provides high strength and durability.

- Girders: The main load-bearing elements. I-beams and box girders are commonly used due to their structural efficiency.

- Deck: The surface on which vehicles or pedestrians travel. It is supported by the steel girders.

- Supports: Includes abutments at the ends and piers in the middle (for longer spans) that hold up the girders.

Steel girder bridges are widely used for their ability to span moderate distances, their relative ease of construction, and their strength, which allows them to support heavy loads. They are common in both highway and railway bridge applications.

Why are girder bridges used?

Girder bridges are used for several reasons, primarily related to their structural efficiency, versatility, and cost-effectiveness. Here are some of the main reasons:

- Strength and Durability: Steel girders provide a high strength-to-weight ratio, making them capable of supporting heavy loads and withstanding various stresses over long periods.

- Versatility: Girder bridges can be designed to span a wide range of lengths, from short spans over small creeks to longer spans over highways and rivers.

- Ease of Construction: The construction process for girder bridges is relatively straightforward. Prefabricated girders can be transported to the site and assembled quickly, reducing construction time and labor costs.

- Cost-Effectiveness: Due to their simpler design and the availability of materials, girder bridges can often be built more economically than more complex bridge types.

- Maintenance: Steel girders can be inspected and maintained relatively easily. Repairs can often be made without extensive disruptions to traffic.

- Adaptability: Girder bridges can be adapted to various geographical and environmental conditions. They can be constructed in different configurations to suit specific site requirements.

- Aesthetics: While functionality is paramount, girder bridges can also be designed to be visually appealing, often incorporating sleek and modern design elements.

These factors make girder bridges a popular choice for many transportation infrastructure projects, balancing functionality, economy, and reliability.