Below is a fully SEO-optimized, long-form blog post on NATM Gantry (around 3,000+ words).

If you want, I can also expand it to 5,000 words, add images, meta title/description, or WordPress HTML format.

Table of Contents

NATM Gantry: A Complete Guide to Design, Working, Types, Installation & Safety (2025 Updated)

Introduction

Tunnel construction has advanced rapidly in recent years—and among modern tunneling systems, the NATM Gantry plays a critical role in safety, speed, and structural precision. Whether you are involved in civil engineering, tunneling projects, underground metro construction, or infrastructure development, understanding the complete working mechanism of an NATM gantry is essential.

This detailed guide explains:

- What an NATM gantry is

- How NATM methodology works

- Types of NATM gantries

- Design, components & structure

- Installation & operation procedures

- Safety standards

- Cost factors

- Applications in Indian & international tunneling

- And the future of NATM gantries

Let’s dive in.

What is NATM? (New Austrian Tunneling Method)

Before understanding the NATM gantry, you must understand NATM itself.

NATM (New Austrian Tunneling Method) is a modern and flexible tunneling technique used worldwide. It utilizes the surrounding rock mass as a natural load-bearing structure, reducing the need for heavy permanent supports.

Key principles of NATM:

- Identify rock behaviour through continuous monitoring

- Make the ground itself load-bearing

- Use controlled blasting or mechanical excavation

- Apply shotcrete (sprayed concrete) immediately after excavation

- Install temporary supports like lattice girders, rock bolts, wire mesh

- Add permanent lining after stability is achieved

NATM is widely used in:

- Metro tunnels

- Road tunnels

- Railway tunnels

- Hydropower projects

- Highway underground passages

- Mining tunnels

But NATM cannot be executed efficiently without the NATM gantry, a crucial support and working platform.

What is an NATM Gantry?

An NATM Gantry is a steel structure (usually a movable frame) used inside tunneling projects to support multiple operations such as shotcreting, rock bolting, wire mesh installation, monitoring equipment placement, lighting, and providing safe working platforms.

It acts as a multi-purpose mobile workstation inside a tunnel.

Functions of NATM Gantry:

- Supports shotcrete application

- Helps in mounting sensors, instruments & utilities

- Provides safe platforms for workers

- Holds working tools and equipment

- Assists in tunnel lining works

- Ensures proper reach to sidewalls & crown

- Improves worker safety

- Enhances accuracy in tunnel profile shaping

Why NATM Gantry is Essential in Tunneling?

1. Safety

Tunneling involves falling debris, uneven surfaces, and challenging conditions. The gantry provides stairs, platforms, guard rails, and lighting to ensure safe operations.

2. Speed & Efficiency

Work moves faster because teams can work simultaneously on:

- Shotcrete

- Steel ribs

- Drilling & bolting

- Wire mesh

- Lattice girder installation

3. Accuracy

Gantry systems ensure uniform shotcrete thickness, precise alignment for supports, and consistent tunnel profile development.

4. Versatility

A single NATM gantry performs multiple operations and is adjustable to accommodate tunnel sizes ranging from 6m to 15m+ in diameter.

Design & Components of an NATM Gantry

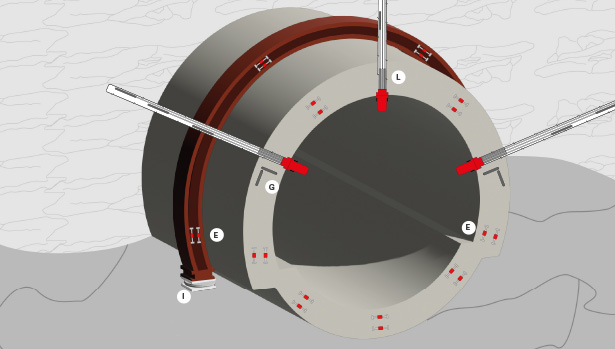

A typical NATM gantry is a heavy-duty modular steel structure equipped with hydraulic, mechanical, and electrical systems.

Major Components:

1. Main Steel Frame

- Built with high-strength steel

- Arch-shaped to match tunnel profile

- Telescopic width adjustments

2. Working Platforms

- Multi-level

- Slip-resistant

- Adjustable height

- Guard rails for safety

3. Wheel or Rail System

Depending on tunnel design:

- Rubber-tyred wheels (self-propelled)

- Rail-mounted wheels

4. Shotcrete Support System

Includes:

- Nozzle holders

- Robot arms (optional in advanced systems)

- Scaffoldings

5. Hydraulic System

Controls:

- Lifting

- Width adjustment

- Platform movement

6. Electrical System

- LED work lights

- Control panels

- Emergency stop systems

7. Safety Mechanisms

- Anti-slip floors

- Guard rails

- Emergency alarms

- Load sensors

Types of NATM Gantries

Depending on tunnel size, purpose, and movement mechanism:

1. Mobile NATM Gantry

- Self-propelled

- Used in long tunnels

- Faster movement

2. Rail-Mounted NATM Gantry

- Moves on rails inside the tunnel

- Stable and highly accurate

3. Fixed NATM Gantry

- Stationary

- Used for small tunnel sections or short-term work

4. Hydraulic Adjustable Gantry

- Height & width can be changed using hydraulics

5. Heavy-Duty Multi-Functional Gantry

- Supports complex metro/hydropower tunnels

- Includes robotic shotcrete arm support

How an NATM Gantry Works (Step-by-Step)

Step 1: Tunnel Excavation

- Drill & blast or TBM excavation (in NATM mostly drill/blast)

- Muck removal

Step 2: Gantry Placement

- Gantry is moved to the newly excavated area

- Platforms are adjusted to match crown and walls

Step 3: Install Primary Supports

Workers use the gantry to install:

- Wire mesh

- Rock bolts

- Lattice girders

- Steel ribs

Step 4: Apply Shotcrete

- Shotcrete nozzle is mounted through the gantry frame

- Uniform layer applied across the tunnel profile

Step 5: Monitoring & Instrumentation

NATM method relies heavily on monitoring:

- Extensometers

- Load cells

- Convergence monitoring points

The gantry holds these instruments.

Step 6: Move to Next Section

Once shotcrete sets, the gantry is moved forward to the next excavation cycle.

Applications of NATM Gantries

1. Metro Tunnels

Used in metro projects like

- Mumbai Metro

- Kolkata Metro

- Bengaluru Metro (Namma Metro)

- Delhi Metro Phase 4

2. Railway Tunnels

Vital for Indian Railways projects (J&K, Northeast).

3. Road & Highway Tunnels

Used in Himalayan tunnels, coastal tunnels & expressway projects.

4. Hydropower Projects

Used for headrace tunnels, surge shafts & cavern construction.

5. Underground Passages

Urban utility tunnels and sewage tunnels.

Advantages of NATM Gantry

✔ Faster installation of tunnel supports

✔ Improves worker safety

✔ High precision for shotcrete and steel supports

✔ Flexible design for different tunnel shapes

✔ Reduces manpower dependency

✔ Supports multi-department workflow simultaneously

Challenges in NATM Gantry Operation

1. Space Limitations

Narrow tunnels need custom gantries.

2. Skilled Manpower

Hydraulic operations require trained operators.

3. Maintenance

Hydraulic leaks, rail alignment, and electrical issues require regular inspection.

4. High Initial Cost

Though operational efficiency compensates long-term.

NATM Gantry Installation Process

Step-by-Step Installation Procedure

- Pre-assembly outside tunnel

Gantry frame, wheels, hydraulics assembled. - Transport inside the tunnel

Using locomotives or manual towing. - Final assembly

Platforms, electric panels, safety rails installed. - Alignment with tunnel profile

Adjust width and height. - Safety checks

- Hydraulic pressure test

- Brake test

- Load test

- Trial run

Gantry moved across a 15–20 m section. - Full-scale operation

Gantry becomes part of NATM cycle.

Safety Guidelines for NATM Gantry Use

1. Follow SOPs

Every project must maintain standard operating procedures for gantry usage.

2. Daily inspections

- Hydraulic pressure

- Wheel alignment

- Platform locking pins

- Lights & sensors

3. Worker PPE

Mandatory:

- Helmet

- Reflective jacket

- Harness

- Gloves

- Steel-toe boots

4. Load Restrictions

No overloading of platforms.

5. Emergency Systems

Ensure functioning of:

- Brakes

- E-stop buttons

- Alarms

Top Manufacturers of NATM Gantry in India

NPEC Siliguri (National Power Engineering Company) is one of the leading engineering and electrical service providers in North Bengal. Known for its reliability, technical expertise, and on-ground service strength, NPEC caters to government, private, industrial, commercial, and large infrastructure projects across Siliguri, North Bengal, Sikkim, and neighboring regions.

Maintenance Checklist for NATM Gantry

✔ Lubricate wheels & bearings weekly

✔ Check hydraulic pipes

✔ Inspect electrical connections

✔ Tighten bolts & nuts

✔ Check scaffold boards

✔ Inspect structural welds monthly

✔ Replace worn-out parts immediately

Future of NATM Gantry Technology (2025–2030)

The industry is moving toward:

- Robotic shotcrete arms

- Fully automatic gantry movement

- IoT sensors for alignment

- AI-based monitoring systems

- Lightweight & high-strength alloy gantries

- 3D scanning for tunnel profile adjustment

This will make tunnel construction faster, safer & more cost-effective.

Conclusion

The NATM Gantry is an essential component of modern tunneling operations. It enhances safety, speeds up construction, supports multiple activities, and ensures structural precision in NATM tunnels. Whether for metro, railway, hydropower, road, or utility projects, a reliable NATM gantry directly contributes to the success and efficiency of the entire tunnel project.